ZipGlo Tension Curtain Rod 28-48 in – fits your doorway

Sliding your hand along the matte-black tube, you notice a modest heft adn the cool, smooth iron under your palm. The ZipGlo Tension Curtain Rod (28–48‑inch) spans the window with a barely noticeable seam where the telescoping sections meet. From across the room it almost disappears into the shadow behind the curtain, but up close the rubberized end caps press snugly and the finish reads as restrained and utilitarian. When you sweep the fabric aside there’s a soft scrape at the join rather than a clatter, a small, lived-in detail that tells you more about its construction than any spec sheet. It sits in the room as a quiet horizontal line—defined in scale and texture, quietly setting the stage for the curtains.

First impressions when you unbox these black tension curtain rods

You set the box on the table, peel back the tape and the first thing you notice is how the rods are packed — each one sheathed in a thin plastic sleeve, with foam caps protecting the ends. Unwrapping one, you feel the weight in your hands; it can register as a bit denser than you’d guessed from the photos, and the matte black finish shows up as a soft, low-sheen surface that catches the light in streaks where your fingers rub it. The telescoping sections sit nested inside one another, and there’s a subtle seam where they meet; when you pull gently they glide with a short, springy resistance, and the end caps give under slight pressure before popping back into place.

There’s a folded instruction sheet tucked into the box and a short metal or plastic connector tucked with the rods — you fumble with it, smoothing the paper and turning the rod over to read any stamped markings. The rubber tips at each end are obvious by touch, slightly tacky and intended to grip; you press one against the counter and it holds its place for a moment. Small scuffs from packaging appear on one piece, nothing dramatic, and the mechanism that will provide tension can be felt as a faint coil motion when you compress the rod — not loud, but present. As you lay the pieces side by side, you find yourself adjusting the cushions on the chair and setting the instruction sheet aside while you eyeball how the rods line up, a practical, hands-on first look rather than a detailed inspection.

What you notice in the black finish, spring coil and mounting pieces up close

When you hold the rod up close, the black finish reads more like a soft satin than a deep gloss; light skims across it and small fingerprints show up if you rub the surface. Run your thumb along the join where the sections telescope and you can feel a slight change in texture where the paint thins at the seam. At the very edges—especially near the ends and the screw-together connection—there are tiny machining marks and,in some pieces,a faint spot where the coating didn’t lay down perfectly. Over a few quick passes your fingers pick up a little dust from the finish,and if you press a bit harder you’ll notice the paint can scuff very mildly where two metal parts contact each other.

Look into the opening at the end and the spring coil becomes obvious: it’s a tightly wound steel spiral that peeks out a little when the rod is compressed. When you compress or extend the rod the coil offers a measured resistance and emits a soft metallic note—more of a subdued click than a sharp spring sound—and you can feel the tension change under your palm. The mounting pieces have a rubbery pad that gives under pressure; push them against a wall and they flatten slightly and leave a faint impression. The caps themselves show injection-mold lines and tiny ridges on the inner faces where they meet the metal, and you can sometimes see the metal end of the rod through a small gap at the centre. When assembled,those pads create friction but also collect lint over time,and the area where pad meets metal often shows the earliest signs of wear.

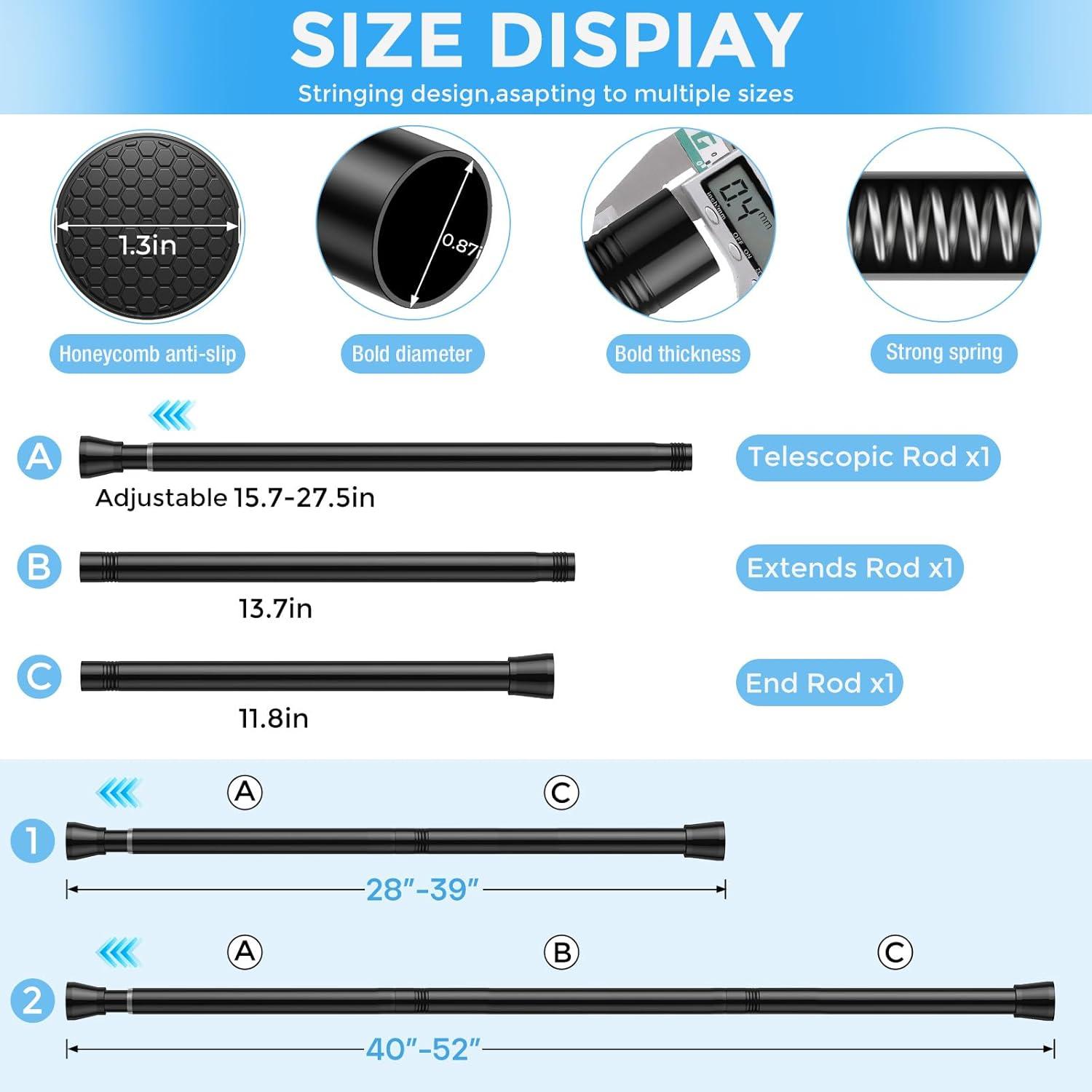

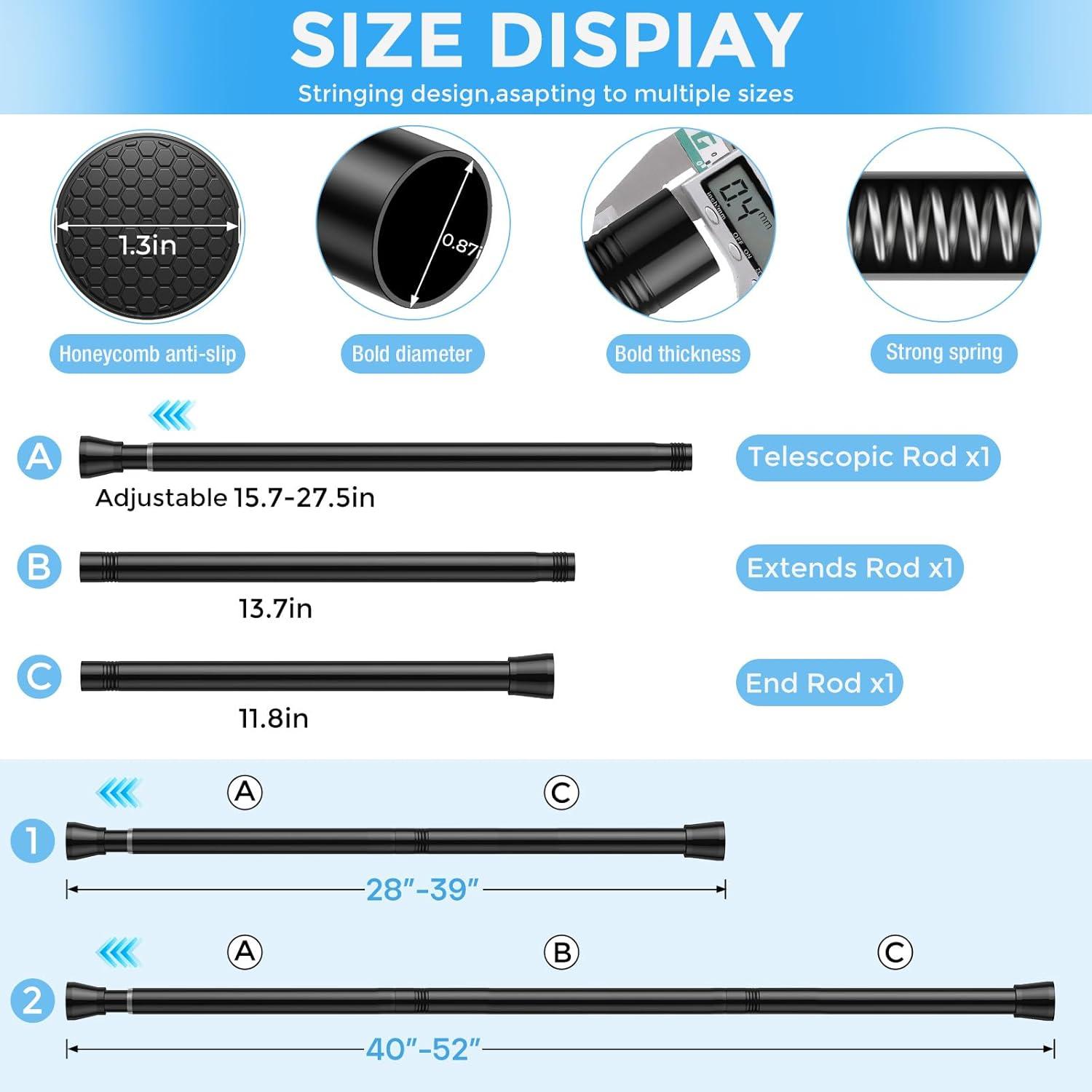

how the adjustable length and diameter relate to your window frames and closets

When you change the rod’s length, what you notice first is how the tubes overlap and where that overlap sits relative to the window jamb or closet opening. Compressing the rod to fit inside a shallow jamb tends to leave the joined section very close to the frame, so the place where the two pieces meet can show through the curtain or catch the curtain header as it passes. Extending the rod to span a wider opening usually shifts that join toward the middle; in everyday use you may find yourself nudging the rod a little to get the tension even on both sides or to keep the join from lining up with a curtain ring or seam.

The rod’s diameter changes how the hanging fabric and any hardware interact with the space. A thicker rod holds the curtain further away from the glass or the closet back wall, which can make the panel hang straighter but also reduces the effective clearance inside a tight jamb or narrow closet. A slimmer rod slips into shallow casings more easily and lets grommets and small clips pass more smoothly, but it can feel firmer under pull and sometimes requires a bit more twisting to achieve stable pressure against the frame. You’ll also notice the end caps pressing against whatever surface you choose to mount on; over time that contact can leave an impression on softer finishes, particularly if the rod is set with strong tension.

| Mount location | Length behavior you’ll see | Diameter effect in use |

|---|---|---|

| Inside jamb | Join sections sit near the frame; less room for curtain headers | Thicker = more clearance from glass; slimmer = easier fit |

| Outside mounting (overhang) | Extra length creates visible overhang; join often ends up centered | Thicker = more visual presence and gap from wall; slimmer = subtler profile |

| Closet interiors | Extension may limit hanger space if pushed forward | Thicker reduces side-to-side room for hangers; slimmer allows smoother movement |

How the non slip pads and spring tension behave when you handle and set them up

When you lift the rod into position, the non-slip pads register instantly — a slightly soft, rubbery feel that compresses as you press the ends against the frame.As you nudge the tube to find the right line, those pads bite against textured paint, wood grain, or drywall; on very smooth or glossy surfaces they can feel more prone to creep, and if the ends meet the wall at an angle the contact patch becomes smaller and the rod is more likely to shift. While you’re fiddling with the length, it’s common to give the rod a few small repositions and to tap the ends with your palm until the pads sit flat and the contact feels even.

The internal spring shows its influence the moment you collapse and expand the sections. When you compress the rod to set it, there’s a clear outward push that resists your squeeze; when fully extended the spring’s force usually feels firm at first and can ease a bit after a few hours or several adjustments. If the curtain or load creates a slight bow in the middle, that outward pressure can feel reduced at the ends, and the pads may need more even seating to maintain grip. During everyday use you’ll notice small changes — a little settling after the first day,occasional micro-shifts when the curtain is tugged,and a subtle difference in how the spring feels after multiple installs — all of which tend to present as gradual,situational behavior rather than sudden failure.

How they look and function in everyday places like your kitchen, bathroom and wardrobe

When you put one of these black tension rods into everyday spots, the first thing you notice is how unobtrusive it can be. In a kitchen window it sits close to the trim and the matte black finish tends to fade into shadows behind a valance or lightweight curtain,so the fabric becomes the visual focus. The rod’s telescoped sections show where they meet if you look up close; that small seam sometimes catches a hooked curtain or the edge of a liner as you slide it, so you may find yourself giving the curtain a quick tug or smoothing it with your fingertips after moving it.

In a bathroom the rod reads more utilitarian. It’s frequently enough placed inside the shower alcove or across a small window, and you’ll see the end caps pressed firmly against tile or painted wood. Because it sits so near the surface, towels or liners hang close to the wall and can feel slightly constrained when you shuffle them; you may unconsciously rotate the rod or nudge the ends to re-seat it after opening a shower curtain. In a wardrobe or closet the rod is used differently: you’ll drape garments directly over it, slide hangers along it, or use it as a temporary crossbar. Under the weight of several hangers it can show a subtle bow in the middle and, for some arrangements, the curtain or items you hang tend to bunch where the rod’s sections join.

| Location | Typical placement | Observed behavior while in use |

|---|---|---|

| Kitchen window | Close to trim or inside recess | Blends with dark hardware; seam at join can catch curtain when opening |

| Bathroom | Across shower alcove or small window | Towels/liners hang close to wall; ends often need a small reseat after movement |

| Wardrobe/closet | As an internal crossbar or temporary hanger | Hangers slide but multiple garments can make the rod bow slightly at the center |

Where these tension rods meet your needs and where you might notice limits in real use

In everyday use the rods generally perform as a quick, temporary mounting point that holds up well at first—curtains slide on, the ends sit flush against the jamb, and the assembly disappears into the background. Over hours and days, though, a few patterns emerge: the joint where two sections meet can catch the curtain as it’s drawn, tension can relax after repeated handling, and the rubber endcaps grip uneven or glossy surfaces less reliably than textured paint or raw wood. These behaviors show up more often when the rod is used for frequent opening and closing or when additional weight gets added to the bar.

Reports collected over multiple placements also point to variation rather than a single outcome. In some setups the rod remains steady for weeks without touch-ups; in others it needs occasional nudging or a short re-twist to recover lost tension. The telescoping pieces that allow length adjustment will sometimes create a small seam under the curtain that makes the fabric snag or bunch while sliding; this tends to be noticeable during repeated motion rather than on first installation. Slip resistance and overall holding power thus feel situational—secure on some walls, less so on others—and can change as the rod is worked over time.

| Common situation | Typical observation |

|---|---|

| light to medium curtains or a closet divider | Usually stable for extended periods with minimal retightening |

| Heavier blackout curtains or added items (hats, coats) | Tends to require occasional adjustment; some reports of sagging or loosening |

| Frequent opening/closing | Joint can snag fabric and tension may slowly relax over days |

| Glossy paint, tile, or uneven trim | Endcaps can slip more easily; grip is more reliable on textured or raw surfaces |

These patterns describe common, observed outcomes rather than fixed strengths or weaknesses; performance frequently enough shifts with placement, how often the curtain is handled, and how the telescoping sections end up aligned. for a closer look at the full specifications and the available size and color options, see the product page here.

What routine adjustments and simple maintenance look like as you live with them

Over the first few days and weeks after installation, the most visible maintenance is mild, ongoing fiddling rather than anything mechanical. the rod often needs a quick twist or a push upward after curtains are opened and closed a few times; the inner tube can creep a fraction, especially when heavier panels move across the seam where pieces join. People commonly smooth the curtain fabric where it catches at that joint, nudge the endcaps back into place with the heel of a hand, or give the whole assembly a half-turn to restore firm contact with the wall. In houses with frequent door traffic or kids pulling at drapes, these small adjustments tend to happen more often; in quieter rooms, they can be months between readjustments.

Simple upkeep mostly consists of keeping contact surfaces clean and watching for gradual loss of tension. Dust and lint collect on the rubber endcaps and along the tube,and wiping them with a cloth is a typical quick fix observed in everyday use. Over seasons, the endcaps can flatten slightly or the telescoping section can be worked a little further in to regain grip — these are common, incremental responses rather than replacements. In some environments minor surface marks or dulling appear on the finish where the rod rubs against the wall; in damp spaces a faint patina may develop over long stretches of time. Overall the pattern is small, situational tweaks: repositioning after a tug, a wipe-down when it looks dusty, and the occasional re-tension when creaks or slipping show up.

| Trigger | Common adjustment observed | Typical frequency |

|---|---|---|

| Heavy curtain pulls or repeated opening | Half-turn/tighten and reposition endcaps | Weekly to monthly, depending on use |

| catching at the rod joint | Smoothing fabric and nudging tube alignment | As needed when curtains snag |

| Visible dust or lint | Wipe endcaps and tube with cloth | Monthly or with regular cleaning |

| Gradual slipping over time | Advance inner tube slightly to restore tension | Every few months in many cases |

How It Lives in the Space

Over time you notice the Tension Curtain Rod Black Tension Rod 2pcs Spring Curtain Rod Non Slip Tension Rods For Windows 28 to 48 Inch No Drilling Adjustable Tension Rods of Curtain Window Closet Kitchen Wardrobe easing into the room’s flow — not new, but quietly steady. As the room is used in daily routines, curtains are nudged aside, hands find the same spot, and a faint wear appears where life meets metal, changing the surface in small, familiar ways. It becomes part of the comfort behavior of the space,present in regular household rhythms and background motion you hardly think about. It stays.

As an Amazon Associate I earn from qualifying purchases.